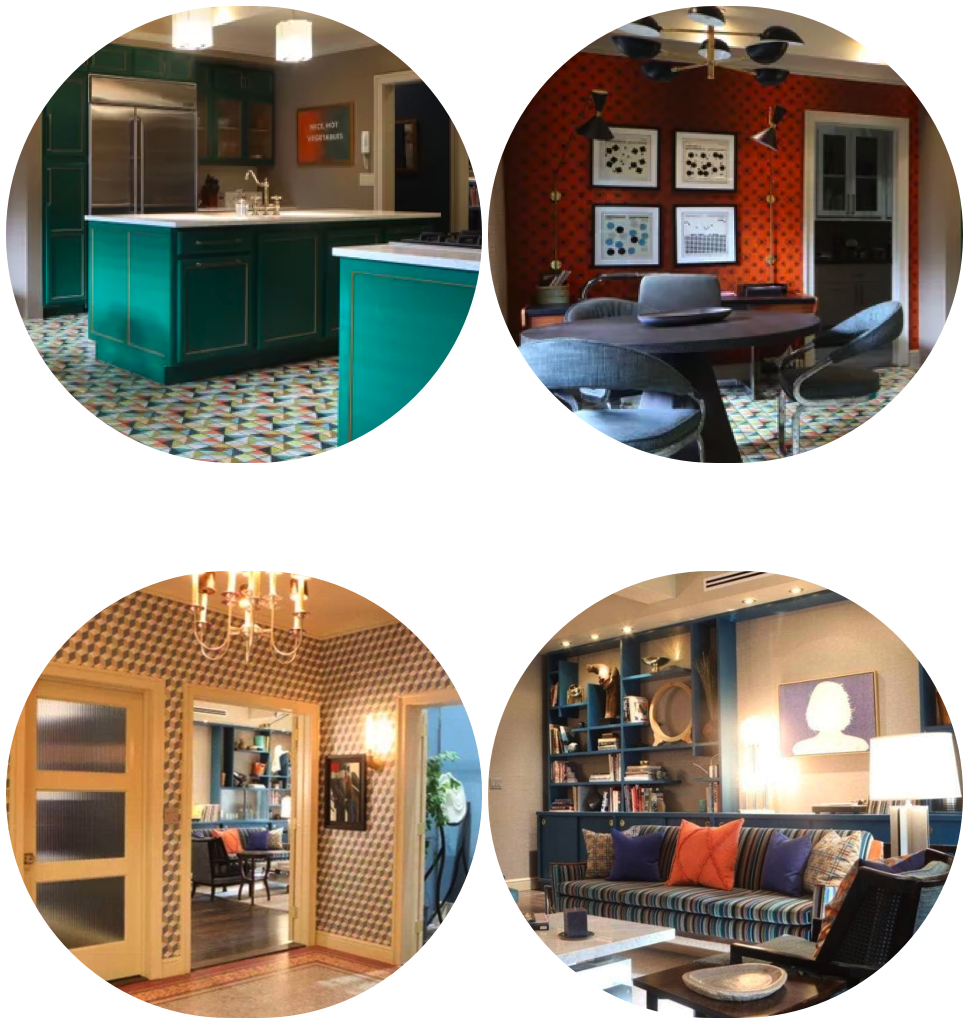

If you have found yourself drawn to any of the apartments in "Only Murders in the Building", it probably says something about your personality. Check out what the design styles of Charles-Haden Savage, Oliver Putnam, or Mabel Mora says about you!

A visit with a family-owned Chinese furniture maker…

Of all the things to do in China, visiting a mom-and-pop furniture manufacturing plant was not something I anticipated. However, when a mutual friend introduced us and offered the opportunity, I (and my flexible family) jumped at the opportunity. They are a mid-sized manufacturer of predominantly doors and children’s furniture, but also has produced bedroom & kitchen furniture. The doors are sold through various different outlets here in the USA, but the furniture is mainly sold in France and Japan.

Three things to know about this company that stand out: 1) This company was started by a woman. While studying in Japan for her MD, Mrs. Liuhan found a job at a furniture company and decided to start one on her own in her native China instead of pursuing medicine. 2) This company uses environmentally friendly adhesives and paints, even if it means importing the raw materials. In a country known for short-cuts and poor materials, going over-and-above for a quality product is a refreshing change! 3) This is a 100% privately owned, family company. The majority of businesses in China have some degree of government involvement and it must take shrewd negotiations with officials to keep their company private. Any one of these could be reason for admiration in a Chinese company, but together it shows the strength and determination by the founding family.

The children’s furniture is simple and adorable, in smooth pastels of gold, lavender, blue, green and pink. Mrs. Liuhan explained the evolution of their designs as we toured the warehouse, even those that came about in light of USA’s recent ban of drop-side cribs. Below is a little bit of the production process they use on their children’s furniture:

- Fun, yet simple, the children’s furniture collection has a cross-style appeal. Mr. & Mrs. Liuhan took us through the process of production for this part of their line.

- After the components are cut on site and a computerized machine drills precise holes (not pictured), a worker hand assembles the sides and backs.

- While doors use a machine sander for a smooth finish, the children’s furniture is all hand-sanded to ensure detailing is not compromised.

- Painting the pieces before rack drying.

- Mr. Liuhan explains the dreaded “B” word…BACKORDERED. In recent weeks, Dalian, China has been unseasonably damp which causes paint to dry unevenly and bubble. Because of this, product delivery is delayed about 1 month. It’s good to know the back story so next time I hear a product is delayed from my end, I can remember Mr. Liuhan and have more grace and patience.

- The furniture is packed and ready to ship! These dressers and desks are visual examples for buyers from France and Japan.

The doors are in a variety of styles and usage…from interior to exterior…and contemporary to traditional. She pointed out the most popular designs in the US and those in China.

Made from pine, alder, or oak, the doors were solid and I was surprised to see the very same doors that grace my own home! It was fascinating to tour the production houses and watch a simple board become an elegant paneled door.

This unplanned visit was a memorable one and we met some very nice people in the process. We wish them all the best in the future!